HOME | 1 | 2 | |

|||

Pontoon Trailer Bunk Brackets |

|||

|

|||

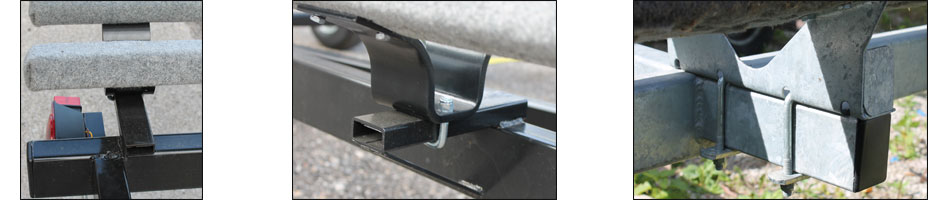

Manufacturers use differing

styles of bunk brackets.

Some brackets are thick

steel formed to shape.

Others are pieces of stamped

steel. The strength is in

the base where the two

pieces of steel that support

the brackets come together.

The reason some companies

need to weld “outriggers” to

their frames is their

frames, and usually axles,

are narrow. Often these

trailers were designed when

pontoons were only 8’ wide.

To get the bunk brackets out

to 77” they need to weld

pieces of steel to extend

the frame. Bunk brackets

distribute the weight of the

boat along the trailer

frame. If you have a modern

heavy pontoon you really

should have 4 or more bunk

support brackets on each

side of the frame. You can

easily spot this, just look

at the number of cross

members supporting the frame

sides. There is a difference in the height of bunk brackets. Most trailers have 4”-5” tall brackets. The boat sits lower on the trailer, launches in shallower water. But some companies have really tall bunk brackets, often as high as 11”. The 7” difference between 5” tall and 11” tall brackets may be the difference in launching in shallow water. |

|||

Almost

as important as the strength

of the bracket is how it’s

attached to the trailer

frame. Attached to the main

trailer frame is the

strongest method, but some

manufacturers don’t have

wide enough frames. Almost

as important as the strength

of the bracket is how it’s

attached to the trailer

frame. Attached to the main

trailer frame is the

strongest method, but some

manufacturers don’t have

wide enough frames.Bunk brackets attached directly to the pontoon trailer main frame cross members are the strongest. The weight of the boat is carried on the cross member, not on some piece of steel welded onto the outside of the frame. More brackets distribute the weight of the pontoon boat evenly along the length of the frame. The more brackets the better. |

|||

| The reason that more companies don’t bolt the bracket to their main frame is because the width of their frame is narrow. To get the bunk brackets out to 77” for the modern pontoons they weld on pieces of steel to extend the width of their frame. Other manufacturers don’t have enough cross braces. They can’t use more bunk supports because they don’t have anything (cross members) to attach them to. | |||

|

|||

| Some Brackets are supported by a piece of steel welded to the frame. | |||

|

|

||

|

This bracket is attached to

2” x 2” steel that’s welded across the top of the frame. |

Welded to the frame is a strong way. But on a trailer with welded bunk brackets, you can only use that trailer for the boat it is built for. | ||

|

Only one brand of pontoon trailers uses the weak bracket shown to the left. The benefit (to a marine dealer) is that it’s easily adjusted. It just takes minutes for the dealer to set up and adjust the brackets for any size pontoon. But will it support a modern pontoon with a large outboard or I/O engine? The only place that you’ll see this type of bunk support bracket is on small fishing boat trailers. Their brackets are probably just fine for 600 lb. fishing boats, but I question its use on a modern pontoon boat especially one with a larger engine. | ||

|

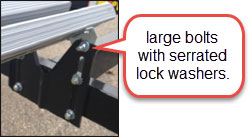

Here’s another heavier duty adjustable bunk bracket. This has large bolts with serrated lock washers, but the weight of your center tube rides on the friction of the two nuts to the bolt. It makes it easy for the marine dealer to adjust the trailer. Again the benefit is to the marine dealer in adjusting the trailer. There is no benefit to the consumer of having the tube ride on two nuts with serrated edges. You may have to recheck and retighten those every time you travel. | ||

| HOME | 1 | 2 | | |||

| PONTOON TRAILERS 101 - FOR EVERYTHING YOU NEED TO KNOW ABOUT PONTOON BOAT TRAILERS | |||