HOME | 1 | 2 | |

|

How Pontoon Trailer Frames are Braced cont... |

|

The trailer to the left is a “private label” trailer. The trailer manufacturer doesn’t put his name on it. The boat manufacturer claims the trailer as his own. The trailer is sold packaged with a new boat. A consumer should be confident that he’s getting a trailer that is “matched” to his boat, as recommended by the new boat manufacturer. If you assumed that about this trailer you could be wrong. The tongue is weak and only the top is welded to the first cross member. The bottom is not welded. The tri-tube support brackets are the type used for fishing boats. On a long trip the weight of the engine and the center tube will put tremendous pressure on this style of brackets. |

|

| Harris Flote-Bote builds beautiful pontoon boats but anyone who knows the stress that pontoon trailers must withstand would recognize this trailer is weak. You should never assume that a boat manufacturer knows anything about boat trailers. It’s a completely different discipline. Private label trailers are covered elsewhere. | |

Some companies understand the stress on the bow of a pontoon trailer. The box (to the left) in the front of this trailer offers good support. The two vertical braces beneath the frame. (The Trailer to the right) is a good way to strengthen the pontoon trailer frame. |

|

I’m not sure the benefit of this type of bracing. BUT at least there is some bracing. |

|

|

|

| There are solutions for trailers with weak bracing, but it’s a lot of work to cut steel, bolt it to reinforce the frame, and then paint it. | |

The weld broke on this trailer. This trailer is for a 20’ pontoon and shouldn’t have had much weight on it. But twisting and flexing can occur on any pontoon trailer. The repair shop did a great job cutting and welding steel. They even added bolts to help brace the trailer tongue. It would have been better had the trailer manufacturer reinforced the tongue in the first place. |

|

|

|

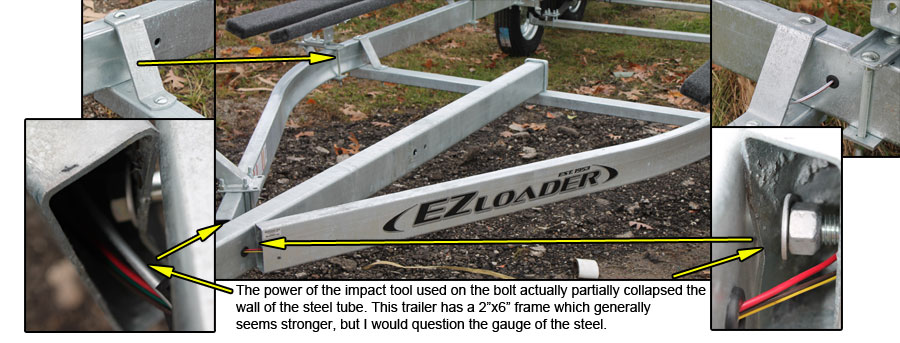

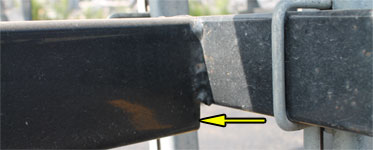

| A disclaimer. I’m not trying to highlight deficiencies in some brands of pontoon trailers. But I’m showing what can go wrong with a bolt together trailer. The manufacturer can exercise all the quality in the world but the trailer assembler can get it wrong. These pictures were taken in Elkhart, Indiana, at a pontoon boat manufacturer. This brand of trailer has an excellent reputation and I usually have a high opinion of this company and their trailers. Yet the picture clearly shows the side wall of this pontoon trailer frame is bent. There were six trailers on display in the boat manufacturers sales lot and all six had dented frames. | |

|

|

| Every now and then I’ll see something I don’t understand. The photo above shows the front tongue attached to the first cross member. It’s a big tongue 4” x 3” steel although the cross member is 2” x 3” steel. This piece carries a lot of weight and, as explained elsewhere, can be subject to flexing stress. One of the most important welds on the trailer is the weld tying this piece to the cross member. The bottom weld is especially critical. The tongue on this trailer is NOT welded all the way around and there is NO weld on the bottom. A 4” x 3” tongue is better than a smaller tongue, if the steel is an adequate gauge, but welding it only on three sides seems to weaken it. Seems like you’d be better off with a smaller piece of steel welded all the way around. | |

| HOME PAGE | 1 | 2 | | |

| PONTOON TRAILERS 101 - FOR EVERYTHING YOU NEED TO KNOW ABOUT PONTOON BOAT TRAILERS | |