HOME | 1 | 2 | |

||||

Pontoon Trailer: Axles, Hubs & Bearings cont... |

||||

| Hubs and Bearings | ||||

|

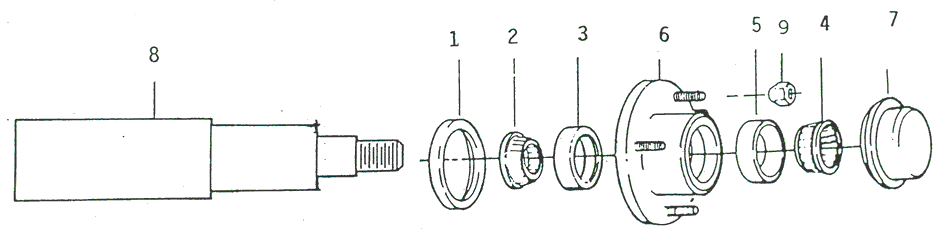

Trailer wheels turn on

spindles and hubs. The end

of the axle has a polished

shaft with a threaded nut on

the end. This is called a

spindle. Bearings rotate in

polished units called races.

A hub that has wheel studs

is attached by a bolt and

covered with a cap. About

the only variation in these

assemblies is the type of

dust cap. Some pontoon

trailers have a grease zerk

designed into the dust cap

(sometimes called a Bearing

Buddy). Others have a grease

zerk beneath the dust cap,

often under a protective

rubber cap. |

||||

Pontoon Trailer Axle "End Unit" |

||||

| 1. Seal | 2. Inner Bearing | 3. Inner Race | 4. Outer Bearing | 5. Outer Race | 6. Hub | 7. Dust Cap | 8. Spindle | 9. Lug nut | ||||

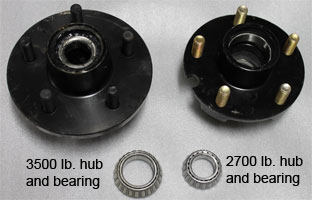

| Hubs are rated by their carrying capacity and have to meet certain Department of Transportation requirements for the rating. Thus a “cheap” hub with imported bearings (and most of them are imported) will do what its supposed to do, even though it’s not a known “national” brand. | ||||

| Size Matters | ||||

Some

manufacturers are always

cutting corners on pontoon

trailers: bias ply tires,

incandescent lighting, and

cheap axles. It’s my opinion

all pontoon trailers should

have 3500 lb. axles. But

2700 lb. or sometimes even

2000 lb. axles are used. The

cost difference isn’t

substantial but a fishing

boat trailer manufacturer

that builds pontoon trailers

may use axles they have in

stock. The difference is in

the size of the hubs and

bearings. A comparison of

the 2700 lb. hub and 3500

lb. hub, shown above,

reveals the difference.

Larger hubs and bearings

dissipate heat better, they

run cooler, and don’t burn

up grease as fast. If you’re

running small tires on 2700

lb. axles you’ll need to

grease the bearings more

often than bigger tires.

Most trailer owners forget

about maintenance and if you

don’t grease the bearings

you’ll realize you have a

problem when you start

seeing smoke. When buying a

new trailer it’s a good idea

to pop the dust cap and

check the grease. You won’t

actually be able to see

grease inside the hub but a

little residue on the zerk

is reassuring. Some

manufacturers are always

cutting corners on pontoon

trailers: bias ply tires,

incandescent lighting, and

cheap axles. It’s my opinion

all pontoon trailers should

have 3500 lb. axles. But

2700 lb. or sometimes even

2000 lb. axles are used. The

cost difference isn’t

substantial but a fishing

boat trailer manufacturer

that builds pontoon trailers

may use axles they have in

stock. The difference is in

the size of the hubs and

bearings. A comparison of

the 2700 lb. hub and 3500

lb. hub, shown above,

reveals the difference.

Larger hubs and bearings

dissipate heat better, they

run cooler, and don’t burn

up grease as fast. If you’re

running small tires on 2700

lb. axles you’ll need to

grease the bearings more

often than bigger tires.

Most trailer owners forget

about maintenance and if you

don’t grease the bearings

you’ll realize you have a

problem when you start

seeing smoke. When buying a

new trailer it’s a good idea

to pop the dust cap and

check the grease. You won’t

actually be able to see

grease inside the hub but a

little residue on the zerk

is reassuring. |

||||

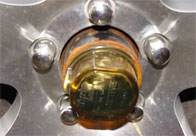

| Oil Filled Hubs | ||||

I’m one to embrace new technology, LED lights, radial tires, disc brakes, etc. We experimented with the oil filled hub and decided that it didn’t make sense for most pontoon trailers. You can search the internet for the benefits and disadvantages. If you are towing frequently and require excellent bearing lubrication, oil filled hubs have benefits. When not towing, condensation can form. They require maintenance and most pontoon trailer owners are not looking for something extra to do. |

||||

The problem with oil filled hubs on an 8’ wide pontoon axle is they are easily knocked off. The oil reservoir sticks out from the hub. Wide axle trailer can hit a curb or dealers moving a trailer will damage the reservoir. This is a common occurrence, we sell dozens of inexpensive replacement dust covers for grease axles a year. When you knock the end unit of a oil filled hub off, it’s a trip to a mechanic to replace the system, (Vault Service kit $219.57 on eBay). |

||||

| How to Grease the Bearings | ||||

|

|

|||

|

Most spindles have a grease

zerk on the end for easy

maintenance. There are

varying types of dust

covers. The common style has

a rubber cap that covers a

hole, you pop out the rubber

cap and the grease zerk is

beneath. Some manufacturers

have special designs and you

don’t need to remove the

rubber cap. I prefer the

style where you put the

grease gun directly into the

grease zerk. With the “zerk

in the dust cap” style there

can be doubt if the inner

and outer grease zerks are

lined up properly. If they

are not lined up all you do

is fill the dust cap with

grease. Some manufacturers

have a closed dust cap that

you have to remove to grease

the bearings. A word of advice in case of a break down. Brand names are usually reassuring to the consumer: Reliable, Dexter, etc. There is however a catch. If you break down and damage the bearings you may have a difficult time finding parts. You may need to contact the trailer manufacturer and have them send you the parts. Many manufacturers buy parts from large distributors. If you breakdown in some remote area you can often go to an auto parts store and buy bearings and a hub. If you have a brand that uses proprietary (hubs made special for their trailers) you may have a wait for repair parts. If you’re going on a long trip, smart individuals will take a spare tire. But a spare hub is a better idea. Hubs cost less than a spare tire and if you have trouble on the road almost any handyman or repair shop can replace trailer bearings or a hub. |

||||

| HOME | 1 | 2 | | ||||

| PONTOON TRAILERS 101 - FOR EVERYTHING YOU NEED TO KNOW ABOUT PONTOON BOAT TRAILERS | ||||